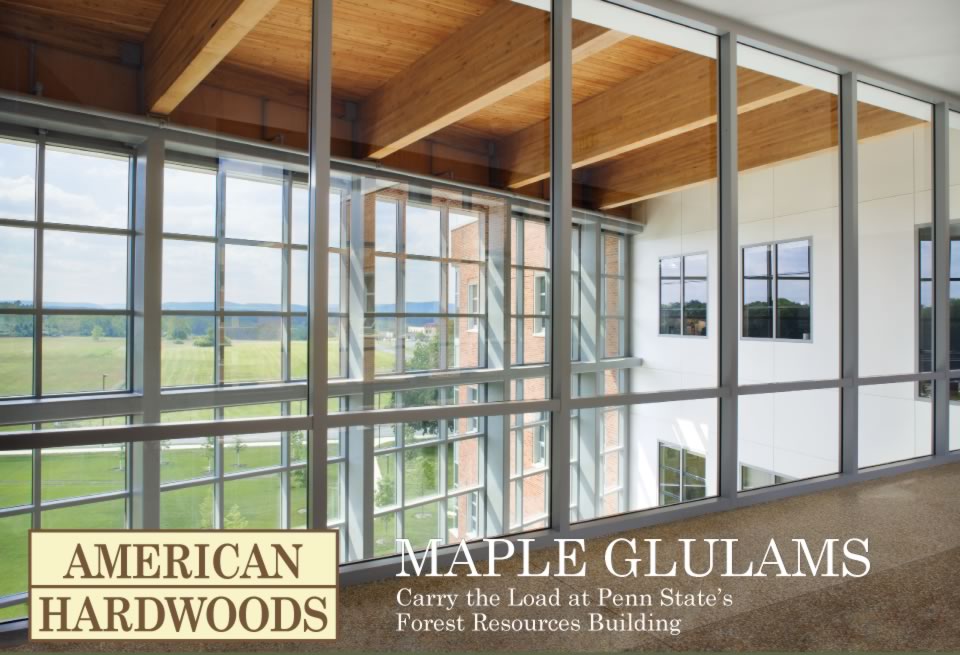

American Hardwoods: Maple Glulams

Carry the Load at Penn State’s Forest Resources Building

The 98,000-square-foot building is the first-ever, large-scale structure supported by soft maple glulam beams. Local cherry lines the stairs and walls. Photography courtesy © Warren Jagger Photography Inc.

The 98,000-square-foot building is the first-ever, large-scale structure supported by soft maple glulam beams. Local cherry lines the stairs and walls. The Pennsylvania State University celebrated its forestry school’s centennial with a Leadership in Energy and Environmental Design (LEED) certified Silver facility, that makes exquisite use of hardwood species native to the region. In a groundbreaking hardwood application, the 98,000-square-foot building is the first-ever, large-scale structure supported by soft maple glulam beams, as opposed to industry-standard softwood glulams. The soft maple glulams were designed using hardwood glulam engineering standards developed by a team of Penn State researchers, in collaboration with the USDA Forest Service. “School of Forest Resources engineers were not only an integral part of the development of the technology, they were instrumental in convincing our engineers that the soft maple beams could support the weight,” said Kevin Aires, AIA LEED, project architect, BLT Architects. University engineers fabricated five soft maple beams—three feet deep and up to 50 feet long—that carry the entire weight of the roof. “The hardwood beams are clearly the showpiece of the entire project,” said Aires. “They fit very well with the school’s mission of utilizing and educating about regional resources.”

Local hardwood was the project’s driving force. While the team did not seek FSC certification for the wood used, the project received credit for LEED-NC MRc5.1 and MRc5.2 because regional sourcing played such a big role. “We were very spoiled as to the amount and quality of local hardwoods we were able to use,” explained Aires. “Even though we had so many species available to us, we limited the wood use to cherry, ash, and red oak, in addition to the soft maple glulams.”

BLT Architects featured cherry in public spaces for paneling, allied seating, trim and millwork. Ash and red oak trim and paneling ornament the conference areas, while red oak cabinetry adorns the labs. Since the paneling was solid and not engineered, panels could only be as large as nature allowed. “Because all the wood was solid, you can really see the grain. In order to highlight this aspect of the design, we went with a clear, natural finish,” noted Aires. “The limitations of panel dimensions were not an issue.”

According to Dr. Charles Strauss, who was the director of the School of Forest Resources at the time of construction, “What really gives this building a flourish is the hardwood we have throughout the public spaces, faculty offices, meeting rooms, and the auditorium. We worked with the architects on the specification of wood finishes because we did not want to use any heavy stains on this beautiful wood.”

In total, the building features over 1,700 linear feet of solid hardwood paneling and over 14,000 linear feet of other hardwood millwork, moulding, and trim. Reaction to the facility has been tremendous. “We have an aesthetic and an aura within this building that is unique to this campus,” noted Strauss. “The overall design of the building creates warmth and an ambiance that is unlike any other structure here at Penn State.”

Dr. Mike Messina, director of the School of Forest Resources, agrees. “Visitors always mention how beautiful our building is. Various campus organizations, offices, and departments request to use our atrium for their presentations, meetings, social gatherings, and so forth,” said Messina.

Local cherry was used for allied seating, trim, and millwork. The doors were manufactured from red oak. Photography courtesy © Warren Jagger Photography Inc.